High pressure liquid pumps

High pressure and ultra-high pressure liquid pumps for plain water service, oil service, injection chemicals, pumping agressive, flammable liquids.

Description

HII high pressure liquid pumps with air drive are widely used for hydraulic tests, high pressure fluids injection, actuation of hydraulic machines and tools.

HII liquid pumps basic line is represented by 45 basic models with a quantity of modifications.

HII high pressure pumps cover a wide range of operating pressures and can solve multitude engineering problems.

Wide production and application experience together with high-tech facilities gives HII advantage in offering high quality engineering solutions for pumping explosive, flammable, chemically active, aggressive liquids at high and ultra-high pressures.

High pressure air driven liquid pumps are the best for maintaining constant pressure at low flow rates, up to zero values.

Features

- Drive type: air drive (all models) / hand operated (3L series);

- Pressure range: 10 - 4,000 bar (150-60,000 PSI);

- Capacity range: 0 - 10 l/min (100 l/min max);

- Maximum flow for each model differs depending on drive type and pressure range;

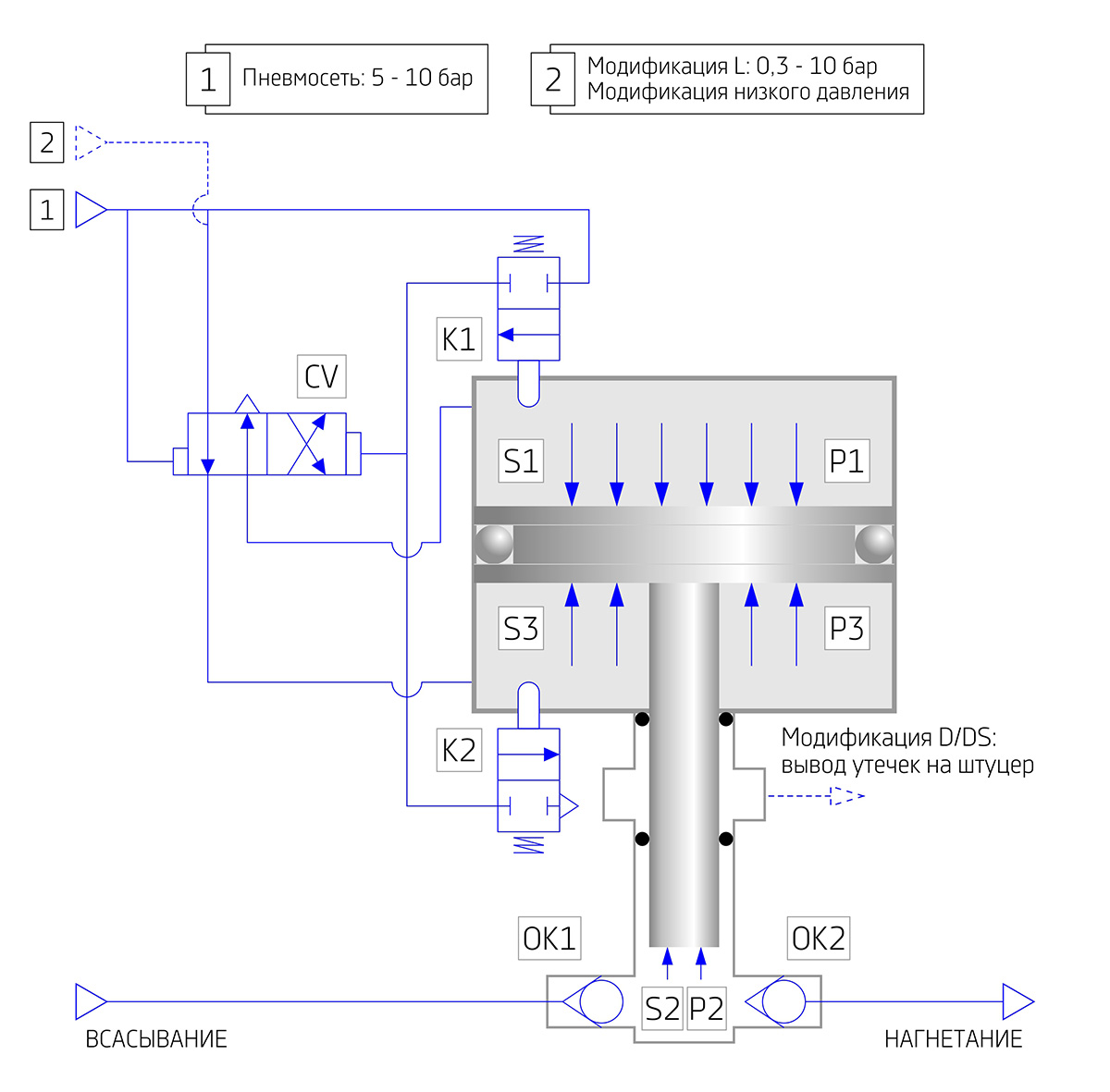

- Pneumatic drive requirements: industrial oil-free air, nitrogen 5-10 bar (70-150 PSI);

- Special versions of pneumatic drives: associated petroleum gas driven, natural gas driven;

- Outlet pressure adjustment: smooth, continious, medium/high accuracy, over a wide range of operating pressures;

- Flow rate adjustment: smooth, continuous, over a wide range of flows, low/medium accuracy.

Advantages

- Do not contaminate the pumped liquid - ideal for pumping high purity liquids;

- Ideal for pressure control tasks - in some modes more efficient than analogues with electric drive in tens, or even hundreds of times;

- Do not heat the pumped liquid in any operating mode - do not require a heat exchanger;

- Do not require bypass valve, bypass line for pressure adjustment;

- Do not require frequency converter. "Automated" operation without automation devices;

- Unlimited start/stop frequency - designed for operation under severe cyclic loads;

- Resistant to hydraulic shock as a result of hydraulic fracturing of the product;

- Very wide, very smooth, very simple and quick adjustment of the outlet pressure and flow in a wide range from zero to maximum values;

- No electric supply required;

- Fire and explosion proof;

- Resistant to long-term operation in dry mode, high cavitation quality, self-priming;

- Compact and lightweight - mobile solution.

Restrictions

- Not designed for pumping contaminated liquids, liquids with mechanical impurities;

- Flow restrictions - not designed for high flows;

- Significantly more expensive than similar electrically driven solutions for hydraulic cutting, washing, blasting, and also pressurizing of the high volume vessels ( >100m3), pre-filling high volume vessels and systems ( >10m3) - where a constant high performance is required;

- Do not pump gas phase;

- Not designed for high-accuracy dosing.

Fluids

- Clean water, industrial water, water with oil products, water with corrosion inhibitors;

- Distilled water, deionized water;

- Industrial oil, hydraulic oil, aviation oil, mineral oil, synthetic oil;

- Brake fluid, Skydrol;

- Hydrocarbons, solvents;

- Antifreezes, ethylene glycol, non-freezing liquids.

- High purity Liquids.

- Explosive, flammable liquids.

- Chemically active, corrosive liquids.