Gas Booster Systems for Chromatography

Gas Booster Systems for Chromatography

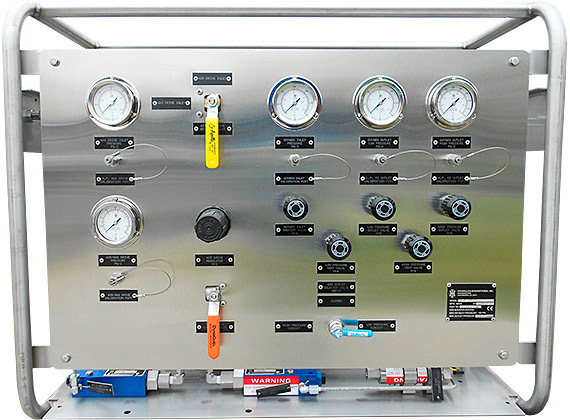

Description

Pneumatic-operated compressor units HII are used in chromatography to supply columns with a movable phase eluent for analysis or separation of mixtures of substances.

The oil-free design of the compressor prevents contamination of pumped gases, which is very important when conducting studies or separating components of especially clean substances.

The high pressure created by the plant allows high and ultra high pressure chromatography. The absence of an electric drive ensures fire and explosion safety, makes it possible to work with combustible gases.

Compressor units are used in laboratory and preparation chromatographs.

Features

- Drive type: pneumatic, electric (built-in supply compressor);

- Pressure range from 10 to 2000 atm (1-200 MPa);

- Compressor element type classification: oil-free - does not contaminate pumped gas;

- Minimum inlet pressure is determined by the compressor element model, but not less than 3 atm;

- The maximum inlet pressure is determined by the compressor element model, typically equal to the maximum discharge pressure;

- Maximum performance depends on the number and type of compressors and the mode of operation;

- Drive power supply: industrial air, nitrogen 5-10 atm (0.5-1.0 MPa);

- Special versions of drives: power supply from associated petroleum gas, methane, electric drive;

- Pressure control: smooth, stepless, medium/high precision, in a wide range of operating pressures;

- Flow control: smooth, stepless, low/medium precision, over a wide range of flow rates.

Advantages

- Entirely clean design of gas part of compressor and valves - no lubrication;

- Do not contaminate gas - ideal for pumping high-purity gases;

- Ideal for charging, constant pressure, recharging;

- Unlimited number of start-up, shutdown cycles - designed for hard cycle load operation;

- Adjustment: smooth, simple, in a wide range from 0 to MAX;

- Fire and explosion-proof

- Manual or automated management: very simple, not highly qualified.

- Small and light - Mobile.

Restrictions

- Compressors are pressurizing: for compressor operation the gas pressure at the inlet must be not less than the minimum required;

- It is not economically feasible to fill gas cylinders with methane from a low-current domestic gas supply network using pressurizing compressors;

- Not designed to pump contaminated gases, gases with mechanical impurities;

- Low capacity equipment - maximum performance is limited;

- Maximum safe oxygen injection pressure: 365 bar;

- Maximum safe air injection pressure: 700 bar. If you need to work at higher pressures, you need to switch to gases that do not contain oxygen.

Fluids

- Air, nitrogen, argon, helium;

- Gases of high and ultra-high purity: oxygen, hydrogen, nitrogen, nitrogen grade 1, nitrogen grade 6.0, helium, argon, krypton, xenon;

- Breathing gases: oxygen, nitrogen, air, breathing mixtures, nightrox;

- Looking for gases: hydrogen, helium;

- Hazardous, fire-hazardous, explosive gases;

- Hydrocarbons other than acetylene: natural gas, synthesis gas, propane, butane, methane, ethylene, carbon monoxide, associated petroleum gas;